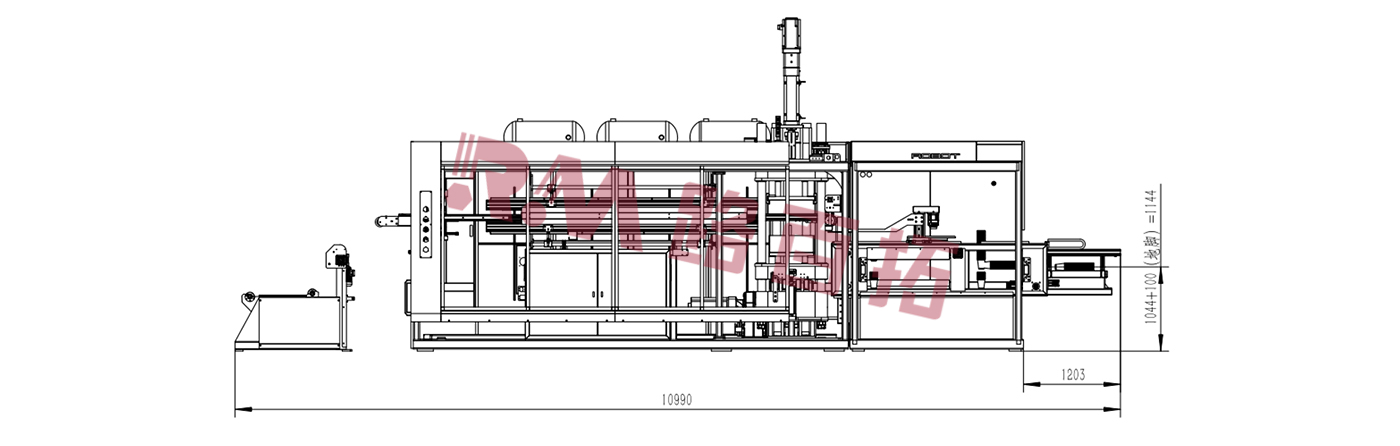

RM 2RH Double Station IMC Thermoforming Machine

Makina a Parameters

| ◆Chitsanzo: | RM-2R |

| ◆Max.Forming Area: | 820 * 620mm |

| ◆Max.Kupanga Kutalika: | 80 mm |

| ◆Kukula Kwamapepala (mm): | 2 mm |

| ◆ Kuthamanga Kwambiri Kwa Air (Bar): | 8 |

| ◆Dry Cycle Speed: | 48/cyl |

| ◆ Mphamvu Yowomba: | 65t ndi |

| ◆ Mphamvu yamagetsi: | 380V |

| ◆PLC: | KEYENCE |

| ◆ Servo Motor: | Yaskawa |

| ◆ Wochepetsera: | GNORD |

| ◆ Ntchito: | trays, nkhonya, mabokosi, lids, etc. |

| ◆ Zigawo Zazikulu: | PLC, Engine, Bearing, Gearbox, Motor, Gear, Pump |

| ◆Zida Zoyenera: | PP.PS.PET.CPET.OPS.PLA |

| Max. Nkhungu Makulidwe | Clamping Force | Dry Cycle Speed | Max. Mapepala Makulidwe | Max.Foming Kutalika | Max Air Kupanikizika | Zinthu Zoyenera |

| 820x620mm | 85t ndi | 48 / kuzungulira | 2.8 mm | 180 mm | 8 mbe | PP, PS, PET, CPET, OPS, PLA |

Kanema wa Zamalonda

Chithunzi cha ntchito

Main Features

✦ Dziwani kuchuluka kwa zokolola zatsopano ndi Makina athu apamwamba kwambiri Opanga ndi Kudulira Apamwamba Kwambiri. Ndi mawonekedwe a masiteshoni awiri, imapanga kupanga ndi kudula nthawi imodzi, kukulitsa kwambiri kupanga bwino. Dongosolo lodulira mu kufa limatsimikizira kudula mwachangu komanso molondola, kupangitsa kuti ntchito yopangira ikhale yabwino.

✦ Mtundu wathu umapereka mphamvu zabwino komanso zoyipa zopanga kukakamiza. Pogwiritsa ntchito kutentha ndi kupanikizika, pepala la pulasitiki limasinthidwa kukhala mawonekedwe omwe amafunidwa. Kupanga kukanikiza kwabwino kumatsimikizira kuti chinthucho chizikhala chosalala komanso chosasinthika, pomwe kukakamiza koyipa kumatsimikizira kulondola kwa mawonekedwe a concave ndi ma convex, zomwe zimapangitsa kuti zinthu zikhale zokhazikika komanso zapamwamba.

✦Pokhala ndi makina opangira palletizing pa intaneti, makina athu amakwaniritsa kusungitsa zinthu zomalizidwa. Njira yophatikizika iyi imakulitsa luso la kupanga ndikuchepetsa kuchuluka kwa ntchito, kulola gulu lanu kuyang'ana kwambiri ntchito zina zofunika.

✦Makina athu ndi oyenera kupanga zinthu zazitali zing'onozing'ono monga makapu a msuzi otayidwa, mbale, ndi zomangira. Komabe, imatha kusintha mosavuta kukula kwake ndi mawonekedwe osiyanasiyana. Mwa kungosintha zisankho ndikusintha magawo, zinthu zambiri zimatha kupangidwa.

✦Gwiritsani ntchito moyenera komanso mwaluso ndi Makina athu Odzipangira Othamanga Kwambiri ndi Odula. Kupanga ndi kudula munthawi imodzi, kukakamiza kwabwino komanso koyipa, kusungitsa makina, komanso kusinthasintha pakupanga zinthu - zonse munjira imodzi yamphamvu. Khalani patsogolo pa mpikisano ndikukweza luso lanu lopanga ndi makina athu apamwamba!

Malo Ofunsira

Makina awa a 2-station thermoforming amagwiritsidwa ntchito kwambiri m'mafakitale onyamula zakudya komanso ogulitsa zakudya. Ndi ubwino wake ndi kusinthasintha, imapereka mabizinesi ndi mayankho apamwamba komanso apamwamba kwambiri opanga.

Maphunziro

Chiyambi:

Thermoforming ndi njira yosunthika komanso yogwira ntchito yopanga yomwe imagwiritsidwa ntchito m'mafakitale osiyanasiyana. Kuonetsetsa kuti kupanga kosasinthika komanso mtundu wapamwamba kwambiri, kukonzekera bwino zida, kugwirira ntchito, ndikusamalira ndikofunikira.

Kukonzekera Zida:

Musanayambe kupanga, tsimikizirani kulumikizidwa kwamphamvu ndi mphamvu zamakina anu a 2-station thermoforming. Yang'anirani bwino zotenthetsera, kuziziritsa, makina okakamiza, ndi ntchito zina kuti mutsimikizire kuti zimagwira ntchito bwino. Ikani motetezeka zisankho zomwe zimafunikira, kuonetsetsa kuti zikugwirizana bwino kuti mupewe zovuta zilizonse zomwe zingachitike panthawi yopanga.

Kukonzekera Zopangira:

Yambani posankha pepala lapulasitiki loyenera kuumba, kuonetsetsa kuti likugwirizana ndi zofunikira za polojekitiyi. Samalani kwambiri kukula ndi makulidwe, chifukwa izi zimakhudza kwambiri kukhulupirika kwa chinthu chomaliza. Ndi pepala la pulasitiki lokonzekera bwino, mumayala maziko a zotsatira za thermoforming zopanda cholakwika.

Zokonda Kutentha:

Tsegulani gulu lowongolera la makina anu a thermoforming ndikukhazikitsa kutentha ndi nthawi. Ganizirani za mawonekedwe a pulasitiki ndi zofunikira za nkhungu pokonza izi. Lolani makina a thermoforming nthawi yokwanira kuti afikire kutentha kokhazikika, kuonetsetsa kuti pepala la pulasitiki likupeza kufewa komwe kumafunikira komanso kuumbika kuti muwoneke bwino.

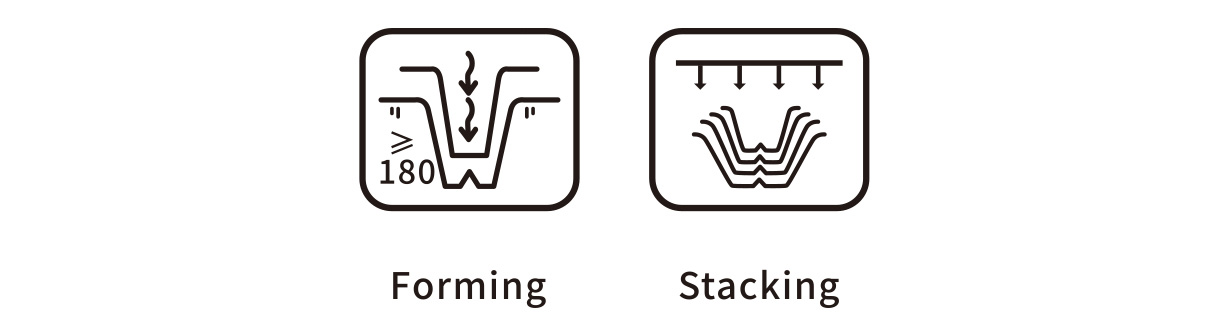

Kupanga - Stacking :

Mosamala ikani pepala la pulasitiki lotenthedwa bwino pamwamba pa nkhungu, kuwonetsetsa kuti yakhala yosalala komanso yosalala. Yambitsani njira yopangira, kupatsa mphamvu nkhungu kuti igwiritse ntchito mphamvu ndi kutentha mkati mwa nthawi yoikidwiratu, ndikujambula mwaluso pepala lapulasitiki kuti likhale momwe likufunira. Pambuyo-kupanga, lolani pulasitiki kulimba ndi kuziziritsa kupyolera mu nkhungu, kupita ku mwadongosolo stacking kuti palletizing bwino.

Chotsani Chomaliza:

Yang'anirani bwino chilichonse chomalizidwa kuti muwonetsetse kuti chikukwaniritsa mawonekedwe ofunikira ndikutsata miyezo yapamwamba kwambiri. Kuwunika mosamalitsa kumeneku kumatsimikizira kuti zolengedwa zopanda cholakwika zokha ndizo zomwe zimasiya kupanga, ndikulimbitsa mbiri yanu yakuchita bwino.

Kuyeretsa ndi Kusamalira:

Kuti musunge magwiridwe antchito a zida zanu za thermoforming, tsatirani chizoloŵezi choyeretsa ndi kukonza. Mukamaliza kugwiritsa ntchito, tsitsani makina a thermoforming ndikuwuchotsa pagwero lamagetsi. Kuyeretsa bwino nkhungu ndi zida kuti muchotse pulasitiki yotsalira kapena zinyalala. Yang'anani pafupipafupi zida zosiyanasiyana kuti muwonetsetse kuti zimagwira ntchito bwino, ndikuteteza zokolola zosasokonekera.